Written by our very own FWF Logistics guest blogger Leroy Eifler, Chief Marketing Officer

Blog Origin: https://lnkd.in/e8Sfe2W

Special thanks to Data Specialties Inc. for hosting us. https://lnkd.in/eEtc_D7

——————————————

KEY CONSIDERATIONS: HOW TO PROPERLY TRANSPORT A MODULAR DATA CENTER

Guest Blogger: Leroy Eifler, Chief Marketing Officer, FWF Logistics, LLC

The growing demands in the data storage industry have led to a boom in Data Center construction over the past few years. In an industry that sends information at or near light speed, reliable transportation to service the centers and the construction of the centers is a must. Recent trends have shown a shift from traditional Data Center construction to Modular-based Data Centers that are customizable, scalable, and can be re-positioned or moved for flexibility previously not available. However, there may be limited roads open for the information superhighway.

When planning construction for a Modular Data Center, transport needs to be at the top of the list. While modular buildings offer flexibility in terms of size and construction, the Department of Transportation may not be as flexible. Often when planning construction of a Modular Data Center, the logistics of moving it are an afterthought. This often leads to challenges with permitting, routing and availability. Any of these scenarios can lead to delayed construction schedules, redesigns or the worst-case scenario of location abandonment.

The first step in developing a Modular Data Center transport plan is to make sure your location is accessible for the buildings to be moved in and placed. Areas can be blocked by low-lying bridges or turns that prevent moving the modules into the prospective site. It is important to know the proposed transport dimensions of the pieces from your supplier to assure they can make it to your desired location. Additionally, it is important to make sure there is enough room on your site to maneuver the buildings into place as they arrive. Too often sites are designed to maximize the use of space, but the team fails to create a transport and rigging plan for bringing the modular buildings in and placing them. Trucks hauling buildings can be over 20’ wide and 120’ long with a very large turning radius, requiring ample room for receiving buildings on a construction site.

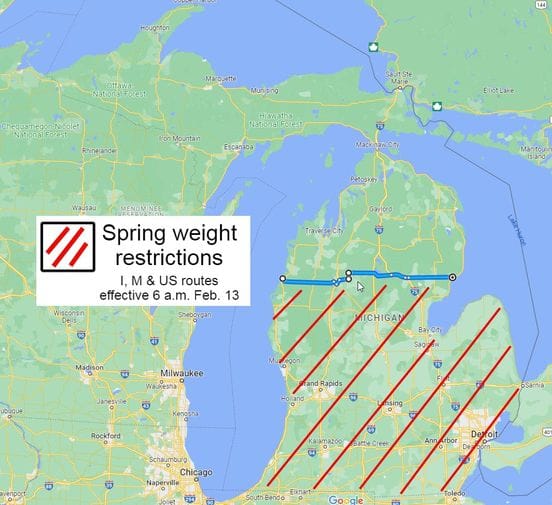

After ensuring that the construction site has both room for the building, as well as for the trucks to deliver them, the next step is to make sure there is accessible route over the road from the supplier to the site. This can be challenging for transporters and manufacturers alike, as it is usually necessary to plan several months before the buildings are even constructed. Proposed routes can change due to construction schedules, weather changes, and a variety of unknown other factors that could occur. The best practice is to ensure that there are multiple routes from the origin to the destination and that you aren’t pushing the envelope too far on the transport dimensions with the design of the building.

Once the buildings have been built and are ready for transport, permitting and scheduling, the focus will be on pick-up and delivery. First, permitting over-dimensional freight can take anywhere from one day to more than two months depending on the size and location of the buildings. Be sure to coordinate with your transportation provider to understand the time requirements to apply for and obtain permits. Second, you will need to understand the delivery schedule requirements. It’s generally possible to get a reasonably accurate estimate, even though trucks may be constricted from perfect delivery estimates due to a wide array of variables. Scheduling also needs to look at shipping volumes. Many times, a group of buildings are sent to a site only to discover they can only off-load one or two per day. It is crucial to make sure that the deliveries are scheduled to ensure off-loading can be done effectively without trucks waiting to be unloaded.

All in all, handling the logistics for Modular Data Centers can be tricky, but it also can operate smoothly if you hire the right professionals for the job. Make sure they have experience, good equipment, a safe operating record, and a willingness to work with you throughout the project. Hiring the right company to handle your transport upfront will ensure that your buildings aren’t stranded when it’s time to deliver.